WHAT ARE VOLTAGE SAGs

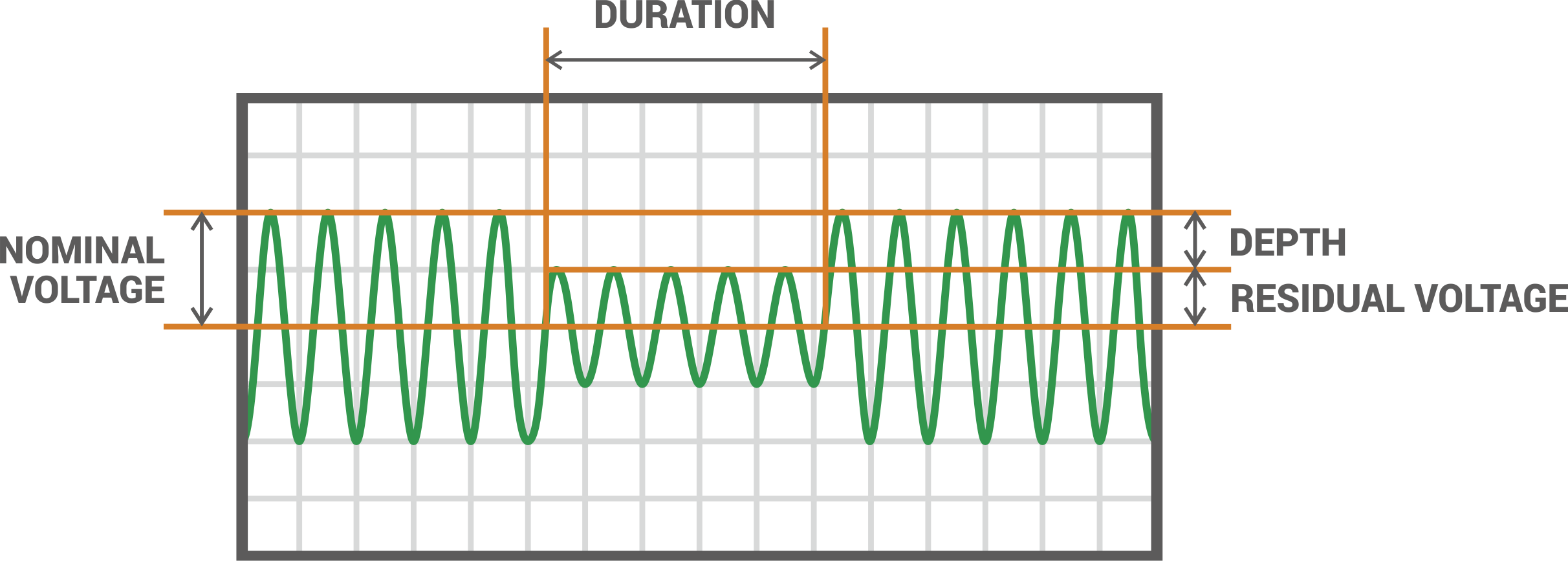

Temporary reduction of the Voltage RMS below a specific threshold at an electrical supply line point.

Voltage SAGs are generally caused by faults in the public network or in the installations of network users, in few cases by transient overloads due to the gearing up of large motors or the switching on of large loads.

Voltage SAGs are unpredictable and random.

SAG starts when Voltage goes lower than 90% of nominal value and ends when voltages resume above 90%. Voltage SAG duration is considered within 10ms up to 1min.

The great deal of Voltage SAG have a duration lower than 1 second and a residual voltage higher than 40% of the rated value.